P-3 Orion Research Group

The Netherlands

this page was last updated on 27 January 2013

History of the Lockheed Martin P-3 Orion

The Neptune and the Electra: "parents" of the Orion

In August 1957 the Chief of Naval Operations (CNO) issued Type Specification No. 146, which contained the requirements for a new, long-range, maritime patrol aircraft for the US Navy. The most important criteria were: more cabin space, a larger radius and a longer endurance then the P-2 Neptune. Furthermore Type Specification No. 146 asked for a short development period and a low cost price per aircraft. This forced aircraft manufacturers to develop the new aircraft as a variant of an existing commercial aircraft. Four aircraft manufacturers responded with a design proposal but Lockheed had the best cards from the beginning. Their design (Model 185) was based on the L-188A Electra which was in development since 1955. The use of the already proven Allison T56-A-10W engines (in use on the C-130 Hercules since 1954) was a big plus: with these turboprops the ideal combination of a high cruise speed for the transit to the operations area and a favourable economical fuel consumption during a low level, low speed mission could be reached. Also Lockheed's experience with Anti Submarine Warfare systems guaranteed success. Finally the development costs and -time were fully in line with Type Specification No. 146.

More than just a military Electra

Naturally the Orion has a lot of commonalities with the Electra, especially in the forward fuselage. The fuselage length of the Electra was not necessary for the Orion and therefore the fuselage was shortened by 2.13 meters; this also resulted in a remarkable weight reduction. All ASW systems and other equipment could easily be installed in the remaining cabin space. A weapons bay was added to the forward fuselage. The Electra's excellent view from the flightdeck was even improved for the Orion by replacing the seven window panels by five larger examples with a flat panel in the middle. Of course the passenger cabin windows disappeared, instead four large bulged observer windows were installed in the fuselage. The Orion's nose radome is a bit more pointed than the one on the Electra and the last major difference is the Magnetic Anomaly Detector that required some design changes to the tail section. This composite stinger houses the electro-magnetic equipment which is used to measure changes in the earth magnetic field like those caused by a submarine. After Lockheed's Model 185 was selected as the Neptune's replacement Lockheed was awarded a "research and development contract" for the production of an engineering mock-up. The company converted the third Electra prototype into an aerodynamic test aircraft with a dummy weapons bay and a dummy MAD-boom. In this configuration (it still had the original fuselage length of the Electra) the aircraft made its maiden flight on 19 August 1958 with the civil registration N1883. On 7 October 1958 Lockheed received a contract for the conversion of this modified Electra into the YP3V-1 prototype. Aircraft N1883 was adapted to meet all the specifications and it also received all equipment selected for the new patrol plane. The aircraft flew again on 25 November 1959, this time with the military serial 148276 which it retained until the end of its USN career in1965. The production aircraft would be designated P3V-1.

Pre-production and operational evaluation

Almost a year after the first flight of 148276 the US Department of the Navy decided that Lockheed was to build a first series of seven pre-production aircraft (148883 - 148889). The P3V-1 was officially given the name "Orion" in November 1960 and a Lockheed crew completed the first flight with a production Orion on 15 April 1961. Before the Orion was approved for operational use the YP3V-1 prototype and the first seven P3V-1's were assigned to several test programs. The Naval Air Test Center (NATC) started the first phase of the Navy Preliminary Examination (NPE-1) at NAS Patuxent River in June 1961. NPE-1 only involved the YP3V-1 prototype. NPE-2, testing production aircraft in an operational environment, was completed in October of the same year. After the incorporation of a small number of design changes, dictated by the USN as a result of NPE-2, NPE-3 was done in March 1962, paving the way for the last phase: the Board of Inspection and Survey (BIS) trials. For BIS six production aircraft were used: five at the NATC and a sixth one at the Naval Weapons Evaluation Facility (NWEF) at Kirtland AFB. BIS started on 16 April 1962 and lasted exactly two months. On 16 June 1962 the P3V-1 Orion was declared suitable for operations with the long range maritime patrol squadrons of the US Navy.

Operational introduction: immediately called for duty

Patrol squadron EIGHT (VP-8) at NAS Patuxent River was the first operational squadron to receive the P3V-1 Orion (149671) on 13 August 1962. The US type designation system was changed on 18 September 1962, resulting in a new type designation for the Orion: P3V-1 changed into P-3A. Introduction of the Orion and the conversion of crews was successful: by the end of October 1962 VP-8 reached operational status with twelve P-3A's. The Orion got the opportunity to prove itself immediately. After the CIA and the US Air Force succeeded in photographing the construction of a Russian SS-4 "Sandal" missile site near San Christobal in Cuba, Orions of VP-8, VP-44 and VX-1 were deployed to Bermuda (Azores). Starting end October 1962 the squadrons performed "round the clock" surveillance operations monitoring Soviet ships during the entire crisis. On 30 April 1963 the first planned deployment with P-3A's was carried out by a VP-44 detachment at Argentia, Newfoundland.

The original mission of the Orion is Anti Submarine Warfare (ASW) and most of the equipment on board is specifically meant for this mission. Detection systems like radar, sonobuoy receivers and the earlier mentioned MAD are a must. In the early days of the P-3 much information collected by these sensors was manually processed and analysed. These time consuming procedures obstructed fast tactical decisions. The strong development and introduction of computers was recognized by the USN and the Naval Air Development Center (NADC) started with the development of "A-NEW" in 1960. This project's goal was to process all operational systems through a single digital computer. The initial plans were completed in September 1962. In October 1963 the YP-3A prototype made the first flight with A-NEW`s first phase (MOD-1) installed onboard. After approval of A-NEW in December 1965 the introduction of the complete system to the fleet was postponed until the P-3C. While developing A-NEW it became clear that some components of the system would be available much earlier then the others, therefore it was decided to introduce A-NEW in several phases. The first step was the "Delayed Time Compression" (Deltic) system which was an improvement of the acoustic systems of the P-3A. The second step was an interim-variant of the Orion: the P-3B. During the first flight of the YP-3C the successor of A-NEW was already in development: the so called Update programs.

P-3A (Alpha) production

The Lockheed California Company at Burbank built a total of 157 P-3A Orions. During the running production three major improvements were introduced. First of all the Orion was modified for mine laying operations. The second improvement was the addition of an Auxiliary Power Unit (APU) to the P-3A's standard equipment, making the aircraft independent from ground equipment. APU's were installed from the 134th aircraft (152164) onwards after initial tests with 152140. Earlier P-3A's were retrofitted. The most important improvement was the installation of "Deltic": the AQA-3 or -4 paper recorders (the same as used in the P-2 Neptune!) were replaced by the AQA-5. This system was able to process data from up to eight sonobuoys while the systems on the original P-3A's could only handle four buoys. Analysis of sonobuoy signals went a lot faster with the new AQA-5 systems. Further improvements included the navigational aids, an acoustic tape recorder and an improved Electronic Support Measures system to receive and analyse radar- and radio signals. The ASR-3 "sniffer", an instrument that sniffed the exhaust fumes of diesel submarines, was removed. "Deltic" was first tested in P-3A 150509 and installed in 152140 and up. Almost all older P-3A's were also modified with the system.

P-3B (Bravo) production

P-3B production started in 1965 and Lockheed delivered the first Bravo's to the NAS Moffett Field aircraft pool on 12 October 1965. The most important difference with the P-3A was the more powerful engines (Allison T56-A-14). These engines did not need the water-methanol injection systems used on the T56-A-10W. The P-3B could be operated from shorter runways, was a better climber and had a higher cruise speed than the P-3A. The last 63 of the total of 144 P-3B Orions have a strengthened fuselage structure allowing the aircraft to take a higher payload. These aircraft were designated P-3B HW ("Heavy Weight"), while previous aircraft were designated P-3B LW ("Light Weight") from that moment. For the USN three Light Weight aircraft were modified to Heavy Weight standard but obviously this was less successful or too expensive because no further modifications were done. All P-3B's were delivered or modified with Bullpup anti surface missile firing systems. In 1966 Lockheed delivered the first export-Orions: five P-3B's for the Royal New Zealand Air Force. In 1968 and 1969 the Australian and Norwegian air forces also received their first factory-fresh P-3B Orions. On 25 March 1969 the Royal Norwegian Air Force took delivery of the very last P-3B.

P-3C (Charlie) production

The first flight of the YP-3C prototype, a P-3B HW modified during the final assembly (153443), took place on 18 September 1968. This aircraft was fitted with the A-NEW integrated ASW system. A Low Light Level Television (LLLTV) system enabled the crew to establish visual contact with surface targets during night and bad weather operations. This made the searchlight (as carried on the P-3A and B) redundant.

The AQA-7(V)1/2 Directional Acoustic-Frequency Analysis and Recording System (DIFAR) is the acoustic system that replaced the Deltic system. The main sonobuoys used in connection with this system are Low Frequency Analysing and Recording (LOFAR) buoys. These passive buoys listen in a wide frequency band to the underwater sounds. Next to these buoys DIFAR-buoys are often used. These have the same qualities as the LOFAR buoys but have the additional plus-point of giving the directions from where the noise comes. The possibilities to launch and receive sonobuoys were substantially improved. The P-3C can carry 84 buoys of which 48 can be pre-loaded from the outside and 36 are carried in the cabin. In the cabin three "A-size" launching tubes (for launching of buoys while the cabin is pressurized) and one larger "B-size" tube (for use without cabin pressure) are available.

The ASQ-114 digital computer has a memory loaded with a large number of sound profiles of submarines and radar- and radio signals for comparing ESM measurements. All this information simplifies the identification of a submarine. A digital datalink system introduced the possibility to exchange tactical data with ground stations, ships or other aircraft. All data gathered by the Orion during a mission can be handed over to the computer of another Orion or other maritime patrol aircraft arriving on station. The P-3C had a double Inertial Navigation System (INS), each with a separate computer to automatically verify the data about position, course and attitude of the aircraft. So many electronic improvements were introduced in the P-3C, that one single aircraft contained more electronic components then all P-3B Orions together! In 1971 the first RP-3D, an Orion specially designed for magnetic research missions, was delivered. In July 1974 Lockheed handed the first P-3F, a simplified export variant of the P-3C, over to the Imperial Iranian Air Force. Six of these aircraft found their way to Iran.

Update programs

Improvements of the ASW systems of the P-3C became known as the Update programs. Update I (P-3C-I) first flew in April 1974. Test and Evaluation Squadron ONE (VX-1) accepted the first of 31 aircraft in January 1975, while VP-19 was the first operational squadron to receive the type. The P-3C-I was equipped with the Omega navigation system that gave the most accurate information in combination with the INS. Furthermore Update I had an improved DIFAR, a computer memory that was increased seven fold and additional tactical displays on Sensor Stations 1 and 2, where the data collected by sonobuoys is processed.

The P-3C-II pre-production aircraft (159889) was delivered to the NADC in March 1977. Update II received a retractable Texas Instruments Infra Red Detection System (IRDS), also known as the Forward Looking Infra Red (FLIR), which replaced the LLLTV. Because of the infra red capabilities the IRDS, compared to the older television camera, delivered highly improved visual images. Other systems in the P-3C-II were improved navigation systems, AQA-7(V)6 (a further development of DIFAR) and provisions to carry and launch Harpoon anti-ship missiles to attack ships from a distance of 60 nautical miles. The most significant improvement was the introduction of the ASR-3 Sonobuoy Reference System (SRS). This advanced system, which makes use of ten aerials, is able to register the exact direction from where a sonobuoy signal is received. Sonobuoy positions are electronically measured and compared with the aircraft's position via the computer. The position of the buoy is presented on the operator's tactical display. With SRS the aircraft can be positioned exactly "on top" and it was no longer necessary to fly over the buoy before initiating the search for a submarine. SRS can also be utilized as a navigational aid in combination with transmitters on ships or other locations. The Royal Australian Air Force received the first export P-3C-II in February 1978, even before the USN introduced Update II for operational use itself (VP-44, May 1978). The CP-140 Aurora, a P-3C variant for Canada equipped with a customer dictated equipment suite, was rolled out on 25 January 1979, followed by the first flight of the type on 22 May.

Starting in March 1981 all Orions (161132 and up) were equipped with a Digital magnetic Tape System (DMTS - selected for Update III), an Integrated Acoustic Communication System (IACS - for communication with friendly submarines) and a Litton LTN-72 navigation system. Furthermore slight improvements were made to the INS and Doppler navigation systems, the VHF communication systems, VOR/ILS (the Instrument Landing System), Tactical Air Navigation (TACAN, a military navigation system making use of ground beacons) and ESM systems. Finally the wing hardpoints to carry weapons were standardized. These Orions were designated P-3C-IIŻ. The USN received its first example in April 1981, while two new Orion operators welcomed their first P-3C-IIŻ in April (Japan) and November (The Netherlands). As the only foreign operator Japan received a license to build their own Orions.

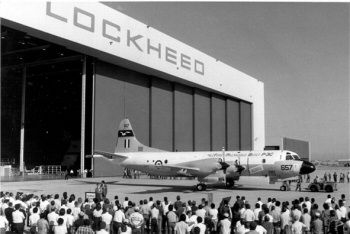

In April 1983 Lockheed delivered the Update III (P-3C-III) prototype (161410), followed by the first production aircraft in May 1984. The advanced IBM Proteus computer system increased the possibilities of DIFAR threefold. Introduction of this system was the biggest improvement compared to the P-3C-IIŻ because of the much faster processing of acoustic data. In 1983 Lockheed started a major move: the P-3 production line was transferred from Burbank to Palmdale. Assembly of the first P-3 at Palmdale started in January 1984 and this aircraft (P-3C-IIŻ A9-657) was delivered to the RAAF in December. Four P-3C-III Orions were delivered to the Norwegian air force in 1989. On 17 April 1990 the last Orion for the USN (163295) was delivered. For the delivery ceremony the very first (and still operational) production Orion (148883) was flown into Palmdale. The Pakistan Navy took delivery of three P-3C-IIż Orions by the end of 1990. These aircraft were used for training of Pakistan Navy crews with VP-30 at NAS Jacksonville but due to a weapons embargo they did not arrive in Pakistan before the end of 1996. The last three airframes of the assembly line at Palmdale were for Canada and became known as CP-140A Arcturus, a simplified variant of the Aurora. Production at Palmdale ended in May 1991, four months ahead of the original schedule.

At the end of 1990 the South Korean government ordered eight P-3C-III+ Orions. Lockheed announced that, due to major reorganizations, all aircraft manufacturing activities were to be located at Marietta, Georgia. Because the entire P-3 assembly line had to move again, the Korean Orions were not delivered before 1995.

Licence production at Kawasaki

On 25 May 1975 a group of specialists from the Japanese Self Defense Agency went to the United States to evaluate the Lockheed P-3C Orion as the possible replacement for the Kawasaki P-2J Neptune. The decision to order a first batch of 45 P-3C-IIŻ Orions to be delivered within a time frame of 11 years was made on 28 December 1977. The Japanese government signed a Memorandum of Understanding which gave them the rights for the production of Orion aircraft in Japan. On 12 April 1978 Kawasaki Heavy Industries was appointed main contractor in the Japanese P-3C production program. Initial components production started as early as 1979 and after Lockheed had built and delivered the first three Orions for the Japanese Maritime Self Defense Force (JMSDF), Kawasaki assembled four aircraft from so-called "knock down kits" supplied by Lockheed. The first of these four aircraft was flown on 17 March 1982. All further JMSDF Orions were manufactured in Japan.

Besides Kawasaki the Japanese government involved four other aircraft manufacturers in the program: the Mitsubishi Heavy Industry Company (production of forward and aft fuselage), the Fuji Heavy Industry Company (production of wings), the Shinmeiwa Kogyo Company (production of nose section, empennage, ailerons and flaps) and the Japan Aircraft Manufacturing Company (nacelles and exhaust pipes). Kawasaki was responsible for the production of the fuselage center section, final assembly and the flight test program. The Allison T56 engines were also produced in Japan. The Ishikawajima Harima Heavy Industries Company (IHI) signed an agreement with General Motors, Allison's parent company, and produced 321 engines between 1981 and 1992.

As a manufacturer of the P-3C Orion, Kawasaki was allowed to authorize changes and improvements to the design up to a certain level. Major changes however had to be reviewed and authorized by Lockheed and the US Navy before implementation to the design. Originally Kawasaki produced P-3C-IIŻ Orions but from the 70th aircraft and up (Japanese Fiscal Year 1988) they followed the Americans and switched to the P-3C-III. In 1987 and 1988 the Japanese naval air force ordered an EP-3 electronic reconnaissance aircraft which was developed by Kawasaki. De first EP-3 rolled out of the factory in Gifu in July 1990. The Kawasaki EP-3 is meant for electronic reconnaissance missions after submarines and surface vessels and is somewhat comparable with the USN EP-3E ARIES II variant. The EP-3 operates at a flight level of 33.000 feet and has a working range of 370 kms. All the electronic mission systems onboard this aircraft were developed domestically by NEC and Mitsubishi Electric. The JMSDF finally ordered a total number of six EP-3 Orions. During 1990 Kawasaki unveiled plans for a series of special variants of the Orion for service with the JMSDF. These included an Electronic Warfare trainer, an oceanographic research version, a systems test and evaluation aircraft and a transport variant. The JMSDF considered the purchase of these variants and in September 1990 it was announced that the 1991 budget contained funds for one NP-3 radar calibration aircraft. Other variants developed are the already mentioned EP-3, the UP-3C EW trainer/support and the UP-3D ESM trainer. The radar calibration capabilities of the NP-3C were integrated into the UP-3C so the NP-3C designation was cancelled. Although Kawasaki is not a state-owned company there are two reasons that make it impossible for them to export the P-3 Orion. First of all it was arranged in the license agreement contract that each and every Kawasaki-produced Orion could only be delivered to the JMSDF. Secondly the Japanese constitution forbids the export of weapon systems. Kawasaki delivered its final P-3C-III to the JMSDF on 17 November 1997. The very last Orion built in the world, Kawasaki's UP-3D (9163) was delivered to the JMSDF on 1 February 2000. This marked the end of 38 years of continuous P-3 production.

© P-3 Orion Research Group / 1997 - 2017